HOME > Turnkey > Turnkey Snack & Sweet > Turnkey Jelly Line > Turnkey Cup Jelly

Turnkey Cup Jelly Production Line Equipment

EDELSTEIN is the professional turnkey equipment manufacturer in Taiwan to offer the total solution of the production machines and the production know-how, recipes and installation technical support of wiring, piping and trial production.

We offer the Turnkey equipment of Cup Jelly Production Line including Cup Filling-Sealing Machine (Semi-auto Table-top Cup Filling Sealing Machine, Rotary type Cup Filling Sealing Machine, In-Line Cup Filling Sealing Machine, Multi-lane Cup Filling Sealing Machine), Drying Machine, Sterilizing Cooler, Material Cooker (Jacketed Steam Kettles) and Storage tank etc.

Are you also interested in other turnkey jelly production line?

What is the key points to choose Turnkey Cup Jelly Production Line Equipment?

Choosing a turnkey cup jelly production line requires consideration of several key points, including:

- Production Capacity: The first consideration when choosing a cup jelly production line is the desired production capacity. The production line should be able to meet the required output without sacrificing quality or efficiency.

- Cup Size and Shape: Cup jelly production lines can be designed to accommodate various cup sizes and shapes. It is important to choose a production line that can handle the desired cup size and shape.

- Filling Method: Cup jelly production lines can use several different filling methods, such as volumetric fillers, piston fillers, or rotary fillers. The choice of filling method will depend on the viscosity and consistency of the jelly being filled.

- Sealing Method: The sealing process is critical to ensure the integrity and freshness of the jelly. Sealing methods include heat sealing, ultrasonic sealing, and induction sealing. The choice of sealing method will depend on the cup material and the packaging requirements.

- Automation and Integration: Automated cup jelly production lines can improve efficiency and reduce labor costs. It is important to choose a line that can be integrated with existing production equipment and control systems.

- Product Safety: The cup jelly production line must be designed to maintain product safety and meet regulatory requirements. It is important to choose a line that is hygienic, easy to clean, and able to handle the specific requirements of the jelly being packaged.

- Cost: The cost of the cup jelly production line is an important consideration for any manufacturer. The line must offer a balance between cost and features to ensure maximum value for the investment.

By considering these key points, cup jelly manufacturers can choose a turnkey production line that meets their specific needs and requirements, and ensure that their products are produced efficiently, safely, and effectively.

What are the most common equipment for turnkey cup jelly production line?

The most common equipment for turnkey cup jelly production line include:

- Cup forming machine: This equipment is used to form the cups.

- Cup filling machine: This equipment is used to fill the jelly material in the the pre-formed cups.

- Lid applicator: This equipment is used to apply lids to the cups once they have been filled with the jelly.

- Sealing machine: This equipment is used to seal the lids to the cups, ensuring the product remains fresh and hygienic.

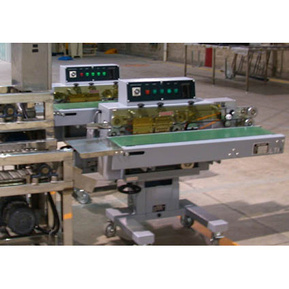

- Cup Filling-Sealing Machine: This machine is integrated multi-functions of cup loading, (optional rinsing), filling, lid loading, lid sealing, printing all together in one machine. That is also often offered by EDELSTEIN for the customer's requirement.

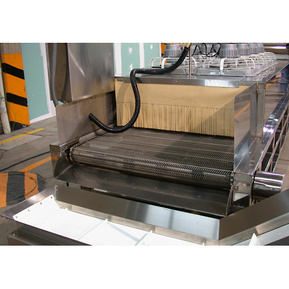

- Sterilization machine: This equipment is used to sterilize the cups and lids before filling to ensure product safety.

- Labeling machine: This equipment is used to label the cups with product information, branding, and other details.

- Conveyor system: This equipment is used to transport the cups between the different stages of the production line.

- Inspection system: This equipment is used to inspect the cups for defects, such as cracks or other damage, before they are filled with jelly.

- Cartoning machine: This equipment is used to pack the cups into boxes for transportation and distribution.

- CIP (Clean in Place) system: This equipment is used for cleaning the production equipment, ensuring hygiene and safety of the production process.

The specific equipment required for a turnkey cup jelly production line will depend on the manufacturer's production needs and the type of cup jelly being produced. By choosing the right equipment, manufacturers can ensure that their cup jelly production process is efficient, safe, and of high quality.

HOME > Turnkey > Turnkey Snack & Sweet > Turnkey Jelly Line > Turnkey Cup Jelly

“Looking for a Packaging machine”?

Just contact “Edelstein International Co., Ltd.”

You will find “Nothing we can’t Pack!”

EDELSTEIN INTERNATIONAL CO., LTD.

No. 396 Ta-tun 11th Street. Taichung 408, Taiwan

Tel: 886-4-22.51.55.06

Fax: 886-4-22.56.93.69

edel@ms36.hinet.net

• • •